Open-Loop Control Systems.

Those systems in which the output has noeffect on the control action are called open-loop control systems

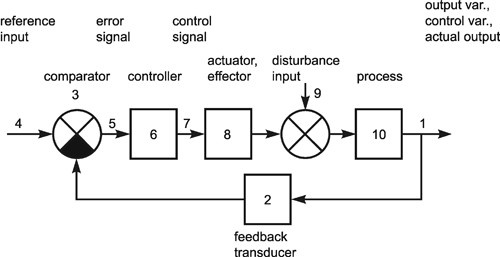

Closed-Loop Control Systems.

Feedback control systems are often referred to as closed-loop control systems.In a closed-loop control system the actuating error signal, which is the difference between the input signal and the feedback signal(which may be the output signal itself or a function of the output signal and its derivatives and/or integrals), is fed to the controller so as to reduce the error and bring the output of the system to a desired value.

|

| CLOSED-LOOP CONTROL SYSTEM |

Advantages of Open Loop

- Less expensive than a corresponding closed-loop system.

- There is no stability problem.

- Convenient when output is hard to measure or measuring the output precisely is economically not feasible.

Disadvantages of Open Loop

- Disturbances and changes in calibration cause errors,and the output may be different from what is desired.

- To maintain the required quality in the output,recalibration is necessary from time to time.

- They are less accurate.

- If external disturbances are present, output differs significantly from the desired value.

TERMS USED IN CONTROL PROCESS

- Variable Process - proses pembolehubah

- Servo Controlled -pengawal serbo

- Feedback -suap balik

- Process -proses

- Set Point -titik mula

- Error -ralat

- Controller -pengawal

- Measurement -pengukuran