JM 507

CONTROL SYSTEM

Experiment 1 : Level Control Demonstration Panel

Control technology is now an integral part of nearly all areas of engineering.Accordingly, a description of its basic principles is a standard feature of technical training programs.

The demonstration model of the RT-6x4 series from G.U.N.T make it possible to ascertain relationship between control parameters in practical experiments and demonstrate these relationships so that they are clear and easily memorizable.

Every model comparises a fully functional system of process with it own control circuit.An extensive use of modern industrial component makes the model are realistic as possible.students thus not only obtain knowledge of basic control principles but also an overview of the control element's design, functionality and application.

The models have a desktop design and require very little maintenance.They are ideal as training aids for laboratory experiments at technical college and universities and intended exclusively for educational purposes.

1.Devices description

- The RT 614 demonstration model is a desktop device to control filling levels.

- Water is used as the operating medium here.Filling levels are controlled by an electronic industrial unit which can be configured as a P, PI, or PID controller.

- Experiments with demonstration model involve modification and adaptation to system control parameters.

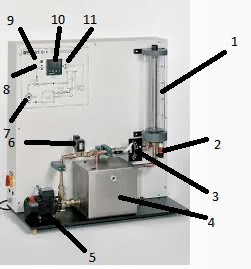

2.Device layout

- The RT614 demonstration model for filling level control has following layout :

- Filling-level cylinder

- Filling-level sensor

- Drain cock with scale

- Water tank

- Pump

- Electric proportional wave

- Pump switch

- Jack for the Y control signal

- Switch for internal/external changeover of the Y control signal

- Controller

- Jacks for the X signal from the filling-level sensor

3.Process scheme

- Filling-level cylinder

- Filling-level sensor

- Controller

- Control valve

- Pump

- Drain cock

- Water tank

4.The controller

- The digital universal controller is equipped with a microprocessor with digitally process input signals and converts them back to analog variable prior to output.

5.Question

E = U - Y

- This relationship is for the summer/subtractor (shown with a green circle)

- This shows how W - the control effort that drives the system being controlled, G - is related to the error. The controller is probably an amplifier - probably a power amplifier - that provides an output to drive the plant, G.

- This shows how the output, Y, is related to the control effort that drives the plant (system being controlled ) with a transfer function, G.

- Note that Y = GW

- Note that W = KE, and use that in the equation for Y. That gives you:

- Y = GW = GKE

- Note that the error is given by E = U = Y, and use that in the equation for Y.

- Y = GW = G(s)KE = GK[U = Y]

- Now, solve for Y, and you get:

- Y = UKG/[1 + KG]

No comments:

Post a Comment